Blog Layout

HOW ERGONOMICS TRAINING CAN BENEFIT YOUR EMPLOYEES AND INCREASE YOUR PROFITABILITY

Ergonomics training is a highly effective program for keeping your employees aligned and aware of their bodies.

Ensuring that your employees remain healthy and safe while on the job boosts morale and increases your company’s profitability. Ergonomics training involves using scientific knowledge of anatomy and engineering to reduce the amount of strain your employees experience while performing normal work tasks. An ergonomics training program is designed to lower the risk of work-related injuries and improve employee productivity and morale through well-being. Increase your profitability by maximizing your workforce’s satisfaction and productivity.

Basics of Training

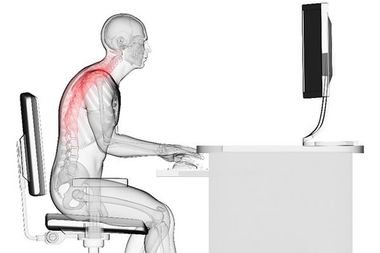

The exact training procedures for ergonomics depend on the type of work environment; your ergonomics trainer will formulate a program based on whether you operate out of traditional offices, retail businesses, construction sites or industrial warehouses. In general, ergonomic training involves teaching employees basic ergonomic principles and how to apply those principles to the workplace. Topics that are typically covered during training include safe work practices, greater awareness of tasks that raise the risk of injury, and the proper use of workplace tools, machines, and equipment. For example, in an industrial ergonomics program, employees who operate heavy machinery would learn how to stand properly while working to reduce their risk of developing lower back problems or other musculoskeletal disorders. Employees who have desk jobs would learn how to position themselves at their computer to reduce strain on their neck and upper back. After going through ergonomics training, employees should also understand how to report workplace injuries or health conditions. Understanding why it is important to recognize and report injuries as early as possible helps ensure that employees receive proper medical care to prevent their condition from becoming worse, potentially leading to work absenteeism.

Benefits of Ergonomics

Ergonomics training provides several benefits for both workers and business owners, including the following:

- Improved morale Employees experience less physical discomfort on the job, which makes them better able to perform well on a consistent basis. Ergonomics training also shows your employees that their employer is taking measures to protect their health and safety, leading to improved relations between you and your employees.

- Increased productivity Ergonomics principles make it easier for employees to do their job efficiently, which helps them become more productive. With the greater ease of movement that ergonomics allows, employees can accomplish more in a typical workday than they would when experiencing discomfort or strain while working.

- Improved attendance Ergonomics reduces the risk that your employees will develop health problems or sustain injuries that cause them to miss work. Employees will also learn to recognize problems early on, resulting in prompt treatment that can prevent injuries from becoming more serious.

Increased Profitability

Ergonomics training can boost your company’s bottom line by ensuring that your employees are working as efficiently as possible. An increase in efficiency and productivity means that work tasks and projects are completed on schedule, leading to satisfied customers and clients. Because ergonomics also decrease the risk of worker injury, you can reduce the costs involved in lost production hours and high-turnover rates. It’s almost always cheaper to keep the employees you have happy than to re-train a replacement.

Fewer injuries and work-related health conditions result in a lower number of compensation claims, which can add up to considerable savings over time. Having an ergonomics assessment can help you determine if your company is doing enough to protect your employees.

For more information about ergonomics training in Arkansas, contact SEA Inc. at 501-568-3111 to speak with one of our certified trainers.

By Derek Jennings

•

19 Apr, 2024

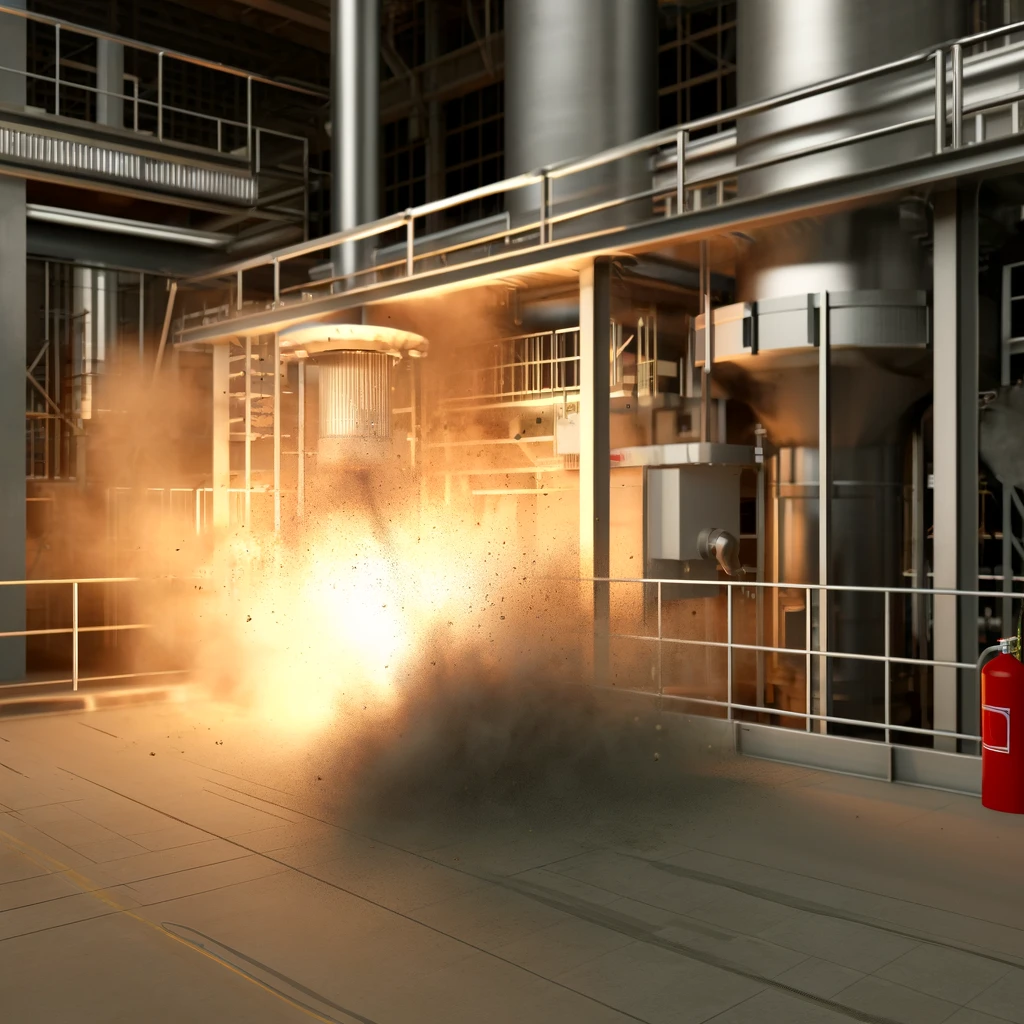

The hazards posed by combustible dust are often underestimated until it's too late. These fine particles, when suspended in the air under certain conditions, can lead to catastrophic explosions, resulting in severe injuries, fatalities, and the destruction of buildings. For example, a tragic incident occurred in a metal processing plant where a combustible dust explosion resulted in the loss of several lives and substantial property damage. This serves as a stark reminder of the potential dangers lurking in what might seem like harmless dust accumulations. While the Occupational Safety and Health Administration (OSHA) has yet to establish a specific standard for combustible dust, it recognizes the severity of these hazards through its National Emphasis Program (NEP) (CPL 03-00-008). This program aims to guide inspections targeting industries known for frequent or severe dust-related incidents, including agriculture, chemical manufacturing, and recycling operations. OSHA also provides valuable guidance materials to help businesses understand and mitigate these risks. What Qualifies as Combustible Dust? Combustible dust can come from a variety of sources, including both organic and metallic materials. These are finely divided particles such as: Metal dusts, including aluminum, magnesium, and some iron forms. Wood dust. Carbon-based dusts like coal and carbon black. Organic dusts from sugar, flour, paper, rubber, soap, and dried blood. Dusts generated from human and animal food processing. Textile fibers and dust. These materials may seem innocuous in larger chunks, but as dust, they can burn rapidly and explosively under the right conditions. The Dynamics of Dust Explosions A combustible dust explosion is more complex than a typical fire. It requires five elements— known as the "dust explosion pentagon": Oxygen (from air) Heat (from an ignition source) Fuel (the combustible dust itself) Dispersion (a cloud of dust particles in a sufficient quantity and concentration) Confinement (an enclosed or semi-enclosed space) If any element of this pentagon is missing, an explosion cannot occur. However, once ignited, the dust cloud can lead to rapid and violent combustion, often manifesting first as a primary explosion within process equipment or enclosed spaces, followed by secondary explosions as additional dust is disturbed and ignited. Preventative Measures and Safety Programs To effectively manage these risks, OSHA recommends conducting thorough hazard assessments that cover: Materials handled. Operations conducted, including by-products. All spaces, even those less obvious. Potential sources of ignition. Implementing a written combustible dust safety program is a best practice for any facility handling potentially explosive dusts. This program should: Define specific safety procedures tailored to the organization. Communicate and ensure understanding of these procedures among all employees. Outline steps to control dust, ignition sources, and potential damage, minimizing injury and property damage risks. How SEA Can Assist You At Safety & Environmental Associates, Inc. (SEA), we understand the complexities of managing combustible dust risks. We offer comprehensive services tailored to your needs, including material testing, dust hazard analysis, hazard classification, and effective grounding techniques. Don't wait for an incident to remind you of the importance of dust safety. Contact SEA today to ensure your operations are safe and compliant. Together, we can create a safer working environment that protects both your workforce and your facilities. By Derek Jennings, President SEA

By Derek Jennings

•

04 Mar, 2024

In a significant move to enhance public safety and environmental justice, the U.S. Environmental Protection Agency (EPA) announced on March 1, the finalization of amendments to the Risk Management Program (RMP). Dubbed the "Safer Communities by Chemical Accident Prevention Rule," this landmark regulation introduces the most protective safety provisions in history for chemical facilities, particularly targeting industry sectors with high accident rates. The rule is designed to shield at-risk communities, especially those in overburdened and underserved areas, from the devastating impacts of chemical accidents. EPA Administrator Michael S. Regan emphasized that this final rule is a vital component of the Biden-Harris Administration's commitment to advancing environmental justice by implementing stronger safety requirements for industrial facilities and new measures to protect communities from harm. Key Provisions of the Rule The final rule mandates more stringent measures for prevention, preparedness, and public transparency, with the aim of preventing accidental releases of dangerous chemicals that could lead to fatalities, injuries, property damage, or environmental harm. Key provisions include: Safer Technologies and Alternatives Analysis : Regulated facilities are now required to perform an analysis of safer technologies and alternatives. In some cases, they must implement reliable safeguard measures to reduce the frequency and severity of accidents. Empowering Workers: The rule advances employee participation, training, and decision making in facility accident prevention. It allows for process shutdowns in the event of a potentially catastrophic release and establishes a process for employees to anonymously report unaddressed hazards. Third-Party Compliance Audits: Facilities with a prior accident history must undergo third-party compliance audits and conduct root cause analysis investigations. - Enhanced Emergency Response: Facilities must ensure timely sharing of chemical release information with local responders and establish a community notification system for impending releases. Climate Change Considerations: Facilities are required to evaluate risks of natural hazards and climate change, including potential power loss, and increase transparency by providing access to RMP facility information for nearby communities. The Impact of the Rule The rule covers all 11,740 regulated RMP facilities across the country, with more rigorous requirements for a subset of facilities that are more accident-prone and pose the greatest risk to communities. According to EPA estimates, accidental releases from RMP facilities cost society more than $540 million each year. Approximately 131 million people live within three miles of RMP facilities, including 20 million who identify as Black or African American, 32 million as Hispanic or Latino, and 44 million who earn less than or equal to twice the poverty level. The rule will be published alongside a query tool which will allow people to access information for RMPs in nearby communities . The agency intends to update the tool in the coming months to allow visualization of climate change hazards, a request of several stakeholders. How SEA Can Help At Safety & Environmental Associates, Inc. (SEA), we understand the complexities of complying with evolving safety standards and regulations. Our team of experts is equipped to assist your company in updating your Risk Management Program to meet the new requirements set forth by the EPA. We offer comprehensive services, including safer technologies and alternatives analysis, employee training programs, third-party compliance audits, and emergency response planning. Don't wait until it's too late and EPA is knocking on your door. Contact SEA today to learn more about how we can help you comply with the new RMP rule and protect your business and the environment. Read more information on the rule visit EPA’s Risk Management Program rule website . By Derek Jennings

By Derek Jennings

•

21 Dec, 2023

Introduction: In recent years, the rise of remote work has transformed the way many companies operate. With more employees working from home or traveling for business, questions about when an injury at home or during a work-related trip is considered work-related for OSHA's 300 Log have become increasingly important. In this blog, we'll explore OSHA's criteria for evaluating work-relatedness in remote work and travel situations to help you navigate these complex scenarios. Remote Work Scenarios: When it comes to remote work, OSHA applies a consistent set of criteria to determine if an injury is work-related. Injuries caused by factors related to the general home environment are typically not considered work-related and are therefore not recordable. To illustrate this, OSHA provides examples to clarify the distinction. 1. Home Environment-Related Injuries: Imagine an employee who tripped over the family dog while rushing to answer a business phone call. In this case, OSHA would classify the injury as not work-related, as it resulted from a non-work-related aspect of the home environment. Similarly, if an employee dropped a box of company documents on their foot at home and got injured, OSHA would classify this as work-related because it occurred while performing a job related task. 2. Clarifying Examples: OSHA further elaborates by addressing specific scenarios. For instance, if a salesperson working from home slipped on ice in their driveway while carrying company documents, OSHA would consider the injury related to the home environment and not work-related. Likewise, if an employee slipped and fell while carrying a company laptop down a stairway at home, OSHA would likely categorize this as a non-work-related injury, as it is still associated with the home environment. On the contrary, ergonomic injuries such as carpal tunnel syndrome from computer use or back injuries from poor posture while working at home are likely to be considered work-related by OSHA since they directly relate to job tasks, rather than the general home environment. Traveling Scenarios: Injuries occurring during job-related travel are generally considered work-related, but OSHA draws a distinction between normal commutes and business travel. 1. Normal Commute vs. Business Travel: OSHA doesn't explicitly define a "normal commute," but it typically refers to the daily journey from home to a fixed work location and back. Injuries during this regular commute are not considered work-related. However, travel between job sites or to another city for business purposes is classified as work related travel. For instance, if an employee drives a considerable distance to a facility they visit only occasionally and gets injured in a car accident, OSHA is likely to classify the injury as work related. 2. Hotel Stays: Employees traveling for business may stay in hotels, creating a "home away from home." In such cases, OSHA advises employers to assess injuries by applying the criteria used for injuries at home. If the injury is directly related to the job, it's considered work-related. However, injuries that occur in hotel facilities like the pool or exercise room are typically not work-related. Meeting with Clients or Customers After Hours: When employees meet with clients or customers after regular working hours, OSHA considers these injuries work-related only if the employee engaged in the activity "at the direction of the employer." In other words, if the employer specifically instructs the employee to meet with clients after hours, injuries that occur during such meetings are work-related. Conclusion: Navigating OSHA's criteria for evaluating work-related injuries in remote work and business travel situations can be complex. Understanding the distinction between injuries related to the job and those caused by the home or travel environment is essential for proper recordkeeping and compliance with OSHA guidelines. By applying these principles, employers can better manage the safety of their remote workforce and ensure accurate injury reporting. By: Derek Jennings

10201 W. Markham Suite 317

Little Rock, Arkansas 72205

Phone: 888-374-3442

1750 Highway 160 West, Suite 101-147

Fort Mill, SC 29708

Phone: 839-400-2223

Our Hours

- Mon - Sun

- Open 24 Hours

© 2024

SEA Inc. | Powered by Flypaper | All Rights Reserved | Privacy Policy