THE TOP 5 MOST CITED OSHA VIOLATIONS AND HOW TO AVOID THEM

Learning about the most common OSHA violations and how they are classified will help you adjust your business model to avoid expensive fines, increase employee safety, and decrease time lost from accidents and investigations.

The Occupational Safety and Health Administration (OSHA) classifies violations of its safety rules and regulations into one of five categories:

Serious Violations

“Other Than” Serious Violation

Willful Violations

Repeated Violations

Failure to Correct Prior Violations

Any of these violations can result in fines of up to $250,000 and possible disruption of your company’s operations. You can avoid these fines and disruptions by ensuring that your employees are properly trained in OSHA safety regulations.

The 5 Most Common OSHA Violations

Use this list of common OSHA violations as a bird’s-eye overview of how your company would fair during an audit. Are you making mistakes that could lead to an expensive citation?

1. Inadequate Fall Protection (1926.501) – 6,721

Slips and falls on construction sites and in manufacturing plants are the number one reason employers receive OSHA citations. According to OSHA guidelines, you must determine if working and walking surfaces have the structural integrity and strength to safely support your employees.

Guardrail systems, personal fall arrest systems, and safety net systems must be in place before you allow your employees to work in areas of higher elevation. Employees using a hoist must also be protected from falling six feet or more by personal fall arrest or guardrail systems.

2. Minimal or Missing Hazard Communication (1910.1200) – 5,192

To avoid violations of hazard communication, you must ensure that the labels on hazardous chemical containers have not been defaced or removed and that the safety data sheets associated with these chemicals are accessible to your employees during each shift.

You, as the employer, must also provide OSHA-approved training to any employee handling hazardous chemicals. The improper handling and disposal of hazardous waste are a health risk to both your employees and your community.

3. Unsafe Scaffolding (1926.451) – 4,295

Scaffolds and scaffolding components that are incapable of supporting their own weight plus four times the weight of its maximum intended load (workers) are a commonly cited OSHA violation. In addition, suspension ropes and all connecting hardware should support six times or more the maximum intended load transmitted or applied to the rope holding up the scaffolding.

4. Improper Respiratory Protection (1910.134) – 3,305

If you fail to provide your employees with the equipment necessary to protect their health, you could be issued an OSHA citation. Respiratory protection is essential for employees working around harmful gases, dust, smokes, vapors, fogs, and sprays.

OSHA lists dozens of different respiratory protectors that are expected to be used by employees working in specific hazardous situations. Some of these respirators include positive pressure, supplied air, and pressure demand respirators. If OSHA finds your employees are not wearing the correct type of respirator according to their guidelines, you will be cited and fined. Familiarize yourself with the proper respiratory protection for your industry’s work environment and implement the correct regulations accordingly.

5. Lockout/Tagout (1910.147) – 3,002

This violation can occur when unexpected energization or startup of your business’s machines or equipment could harm an employee. This is an important regulation for the safety of employees who are required to repair or service heavy equipment and for employees who have to work in proximity to conductors and other electrical hazards.

To avoid injury, you must utilize both lockout devices – a device that ensures machinery cannot be powered on until the device is removed – and a tagout device – a tag that clearly indicates the use of an energy isolating device. Tagouts ensure that machinery is not used until the device blocking power is safely removed.

Preventing OSHA Violations

Although OSHA representatives may seem overly exacting during an inspection, these common OSHA violations are all avoidable job hazards that can be prevented with the proper training and instruction from a qualified safety consultation firm.

For more information about OSHA training, contact SEA Inc. at 501-568-3111 to speak with one of our certified trainers.

Each year, as the Occupational Safety and Health Administration (OSHA) releases its list of the top 10 workplace safety violations, a pattern emerges that begs a question: Are these frequent violations a sign that employers continue to struggle with the same safety issues, or does it reflect a disposition among OSHA inspectors to focus on areas where they are trained to focus? The Persistent Issue of Repeated Findings The repetition of certain violations year after year might seem surprising, but it underscores a significant challenge in workplace safety management. The top violations tend to be those that are most visible and easiest to spot during inspections, such as fall protection and hazard communication. This consistency suggests that while awareness is high, practical implementation and adherence to safety practices lag behind. Top 10 Most Cited Health and Safety Standards of 2024 1. . Fall Protection, General Requirements: 6,307 violations For the 14th consecutive year, fall protection tops the list of OSHA's enforcement priorities. This emphasis is not arbitrary; OSHA has designated fall protection as a national emphasis area, making it a primary focus during inspections. It's often one of the easiest violations to spot without extensive investigation skills. The OSHA standard 1926.501 mandates that employers must provide fall protection systems like guardrails, safety nets, or personal fall arrest systems for workers at risk of falls of six feet or more in construction and four feet in general industry. Often, the major factor in these violations is human behavior. Many offenders might think, "No one is watching, and this will only take a moment, so it's no big deal." However, this mindset can lead to non-compliance with critical safety measures, putting worker safety at significant risk.

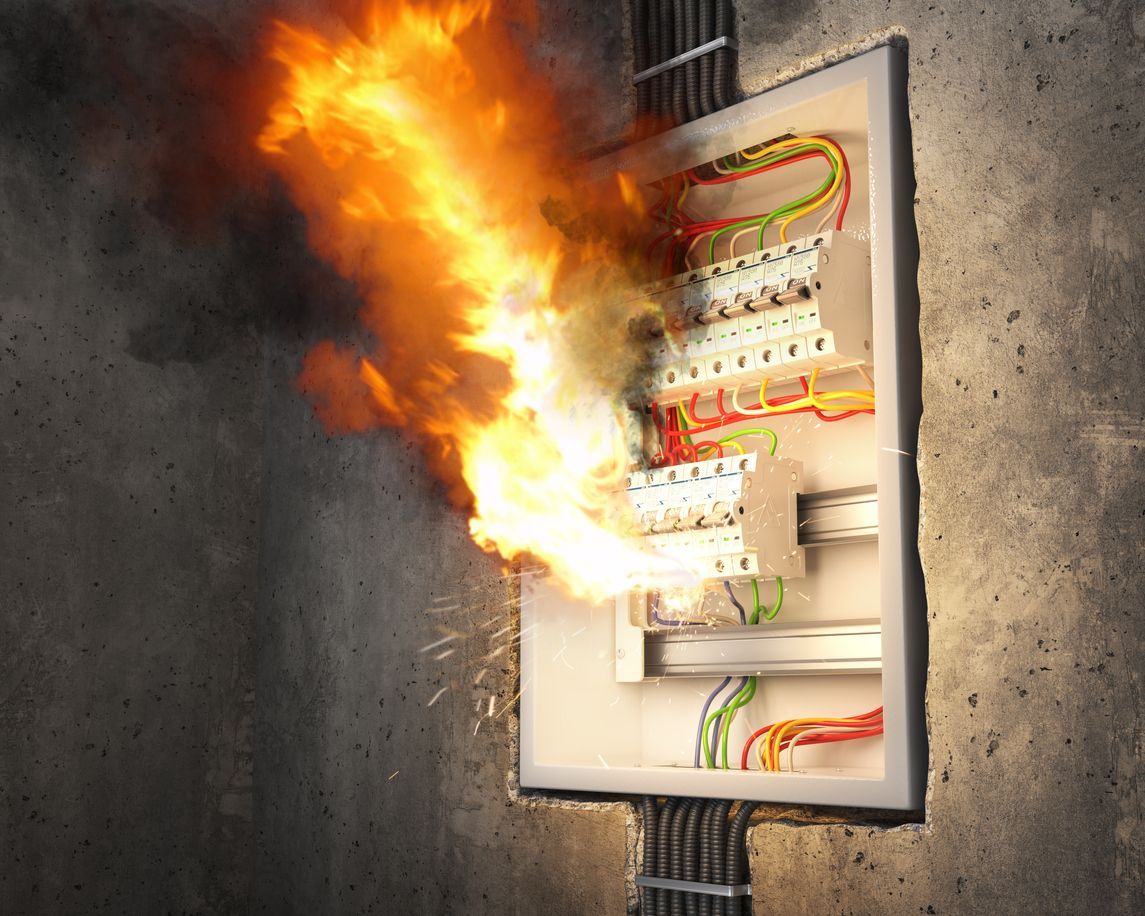

The Occupational Safety and Health Administration (OSHA), in collaboration with the Partnership for Electrical Safety and KEMA Laboratories, has recently unveiled new guidance aimed at addressing arc flash hazards in the workplace. This guidance is a crucial update that highlights the need for comprehensive electrical safety programs that specifically include measures to protect against arc flash hazards. Here’s what employers need to understand about the new directives and how they can effectively respond. Understanding Arc Flash and OSHA's Recommendations An arc flash is a type of electrical explosion that results from a low-impedance connection to the ground or another voltage phase in an electrical system. The new guidance provided by OSHA not only offers a clear definition of what constitutes an arc flash but also elaborates on methods to mitigate such hazards during electrical work. The guidance includes detailed documents for employers and useful handouts for employees, emphasizing the common myths and the reality of arc flash dangers. The Role of NFPA 70E OSHA’s guidance strongly correlates with the standards outlined in NFPA 70E, the National Fire Protection Association’s standard for electrical safety in the workplace. Employers who are already compliant with NFPA 70E likely have a written Electrical Safety Program (ESP) that includes protocols for arc flash hazards. This new guidance serves to reinforce the importance of these existing standards while also urging those without comprehensive plans to take immediate action. What if You Don’t Have a Comprehensive ESP? For employers who have yet to develop an ESP that addresses arc flash hazards, OSHA’s guidance is a wake-up call. It is crucial to recognize that general workplace safety standards, although not specifying arc flash, require protection against electrical hazards under regulations like 1910.333. The absence of specific OSHA standards for arc flash does not excuse employers from the responsibility of protecting their employees from such risks. Implementing Effective Arc Flash Protection Measures Incident Energy Analysis: A foundational step in arc flash protection is conducting an incident energy analysis. This process involves studying the facility’s electrical systems to calculate the potential energy released in the event of an arc flash. Understanding this energy potential is essential for determining the arc flash boundary—the distance within which a person could receive second-degree burns or worse if exposed to an arc flash. Developing a Risk Assessment Procedure: Employ ers need to establish a procedure for assessing the risks associated with arc flash. This includes evaluating the tasks being performed, the condition of the electrical equipment, the maintenance history of the equipment, the energy involved, and the potentia l for human error. Deciding on Protective Measures: Once risks are assessed, decisions must be made regarding the best ways to protect employees. This often involves the use of Arc-Rated Pe rsonal Protective Equipment (PPE) and could also include engineering controls such as redesigning parts of the electrical system to minimize arc flash risks. Proactive Versus Reactive: The Choice is Yours The latest guidance from OSHA should be viewed as an unofficial yet critical call to action for employers to either update their existing safety measures or develop new protocols in line with NFPA 70E. Being proactive about electrical safety not only helps in compliance with OSHA’s standards but fundamentally enhances the safety and well-being of employees. Final Thoughts The introduction of OSHA’s arc flash guidance is a significant step toward heightened awareness and improved safety practices surrounding electrical hazards in the workplace. Employers are encouraged to review their current safety protocols, educate their workforce about the dangers of arc flash, and implement comprehensive measures to prevent such incidents. Always keep in mind that workplace safety begins with staying informed and well-prepared. Make it a habit to test before you touch it and prioritize safety like your life depended on it! For more insights into workplace safety and compliance, keep following our blog. Your safety is our priority, and together, we can foster a safer working environment for all. By Derek Jennings President SEA